- +86 15738871677

- +86 15738871677

- ec22@zkcorp.com

Capacity: 1000-20000 tons per year

Final Product: Battery Grade Industrial Lithium (Li2CO3)

Main Material: Spodumene, Lepidolite

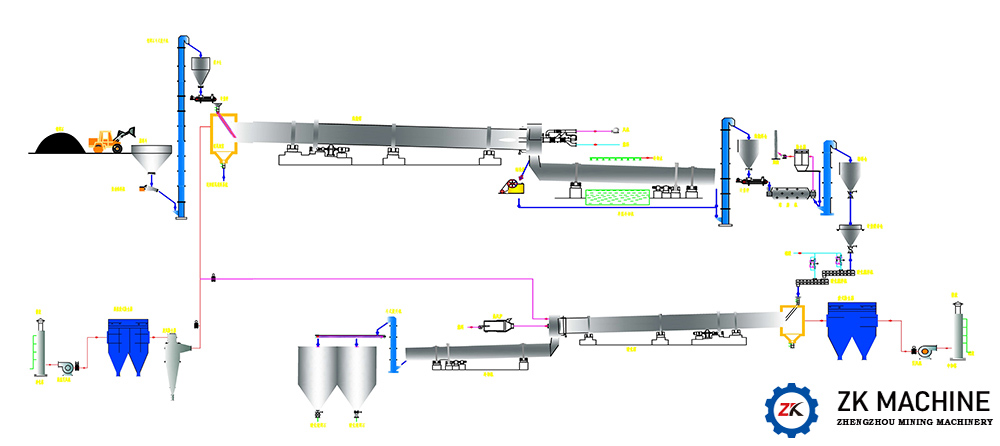

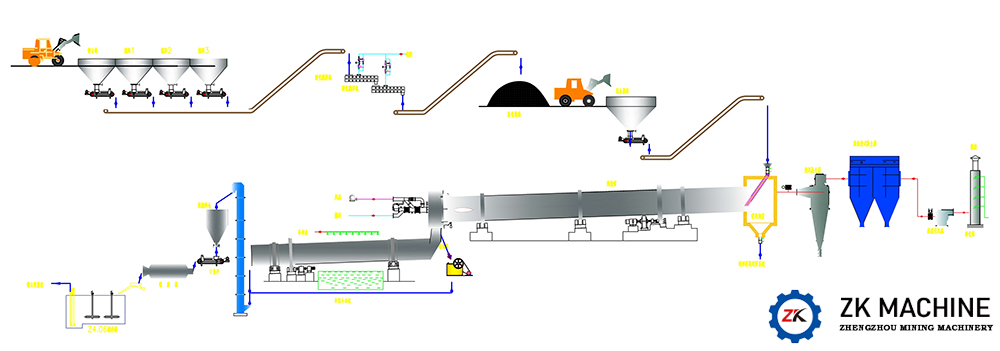

Main Equipment: Roasting Kiln, Acidizing Kiln, Cooler, Ball Mill, Bag Filter

| Final Products | Annual Output(t/a) | Spodumene Amount(t/h) | Main Equipment Model | ||

|---|---|---|---|---|---|

| Conversion Process | Acidification Process | Ball Mill | |||

| Lithium Carbonate LiCO3 | 5000 | 5-6 | Roasting Kiln:φ2.8×50m; Cooler: φ2.6×40m | Acidification Kiln:φ2.8×50m; Cooler: φ2.4×35m | φ1.83×6.4m |

| Lithium Carbonate LiCO3 | 10000 | 10-12 | Roasting Kiln:φ3.5×60m; Cooler: φ2.4×40m | Acidification Kiln:φ3.5×50m; Cooler: φ2.4×40m | φ2.4×8m |

| Final Products | Annual Output(t/a) | Spodumene Amount(t/h) | Main Equipment Model | ||

|---|---|---|---|---|---|

| Conversion Rotary Kiln | Acidizing Rotary Kiln | Ball Mill | |||

| Battery Grade Lithium Carbonate LiCO3 | 10000 | 23-25 (dry basis) | Conversion kiln: φ4.3×68m, with three-stage preheater; Converted material cooler: φ3.8×40m (spray water) or grate cooler | Acidification kiln: inner jacketed hot blast furnace φ3.5×50m; Acidified material cooler: φ3.5×50m (external water spray) | φ3.2×13m ball mill or ZKRM19.3 vertical mill |

| Industrial Grade Lithium Carbonate LiCO3 | 1764 | ||||

| Anhydrous Lithium Hydroxide Li(OH)(Li(OH)>=56.5%) | 10000 | ||||

| Anhydrous Sodium Sulfate(Li2O 0.1%) | 48550 | ||||

| Leaching Residue(Li2O 0.3%) | 210000 | ||||

| Final Product | Annual Output of Lithium Carbonate(t/a) | Amount of Mixed Raw Materials (about 60% of Lepidolite) (t/h) | Main Equipment Model | ||

|---|---|---|---|---|---|

| Rotary Kiln | Cooler | Ball Mill | |||

| Lithium Carbonate LiCO3 | 3000 | 15-18 | φ3.5×60m | φ2.5×23m | φ1.83×6.4m |

| Lithium Carbonate LiCO3 | 5000 | 25-30 | φ4.2×72m | φ3×45m | φ3.2×13m |