- +86 15738871677

- +86 15738871677

- ec22@zkcorp.com

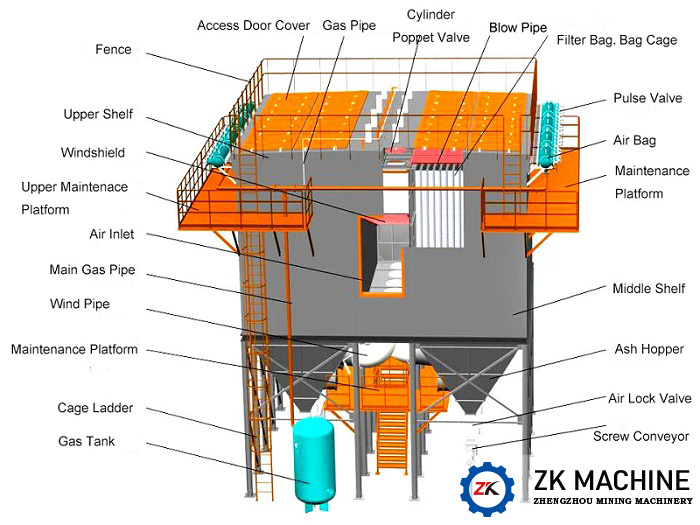

Volume: 67300 - 314000 (m³/h)

Filtration area: 935 - 4361 (㎡)

Net filtration area: 4205 (㎡)

Dust content at inlet: < 1300 (g/m³)

According to different Bag Quantity, Pulse Dust collector could be classified as 32 bags/room, 64 bags/room, 96 bags/room, 128 bags/room. Each kind will be divided into many different type-33 kinds in total.

| Model | PPC96-4 | PPC96-5 | PPC96-6 | PPC96-7 | PPC96-8 | PPC96-9 |

PPC96- 2×5 |

PPC96- 2×6 |

PPC96- 2×7 |

PPC96- 2×8 |

PPC96- 2×9 |

PPC96- 2×10 |

|

| Air volume (m³/h) | 26800 | 33400 | 40100 | 46800 | 53510 | 60100 | 66900 | 80700 | 94100 | 107600 | 121000 | 134500 | |

| Air speed (m/min) | 1.2~2.0(Filtering speed should be determined by different dust collecting location) | ||||||||||||

| Total filtering area (m²) | 372 | 465 | 557 | 650 | 744 | 836 | 929 | 1121 | 1308 | 1494 | 1681 | 1868 | |

| Net filtering area (m²) | 279 | 372 | 465 | 557 | 657 | 744 | 836 | 1028 | 1215 | 1401 | 1588 | 1775 | |

| Qty of bag(pc) | 384 | 480 | 576 | 672 | 768 | 864 | 960 | 1152 | 1344 | 1536 | 1728 | 1920 | |

| Pressure drop (Pa) | 1470~1770 | ||||||||||||

| Negative pressure (Pa) | 5000 | ||||||||||||

| Inlet dust concentration (g/m³) | < 1300 | ||||||||||||

| Outlet dust concentration (mg/m³) | ≤30 | ||||||||||||

| Air cleaning compressed ain | Pressure (MPa) | 0.5~07 | |||||||||||

| Consumption (m³/min) | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3 | 3.4 | 4.2 | 4.8 | 5.4 | 6 | |

| Pulse valve | Qty(pc) | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 14 | 16 | 18 | 20 |

| Size(inch) | 2~1/2” | ||||||||||||

| Lift valve (with cylinder) | Qty(pc) | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 14 | 16 | 18 | 20 |

| Size (mm) | Dia.Of lift valve:Φ725,Dia.Of cylinder:φ100 | ||||||||||||

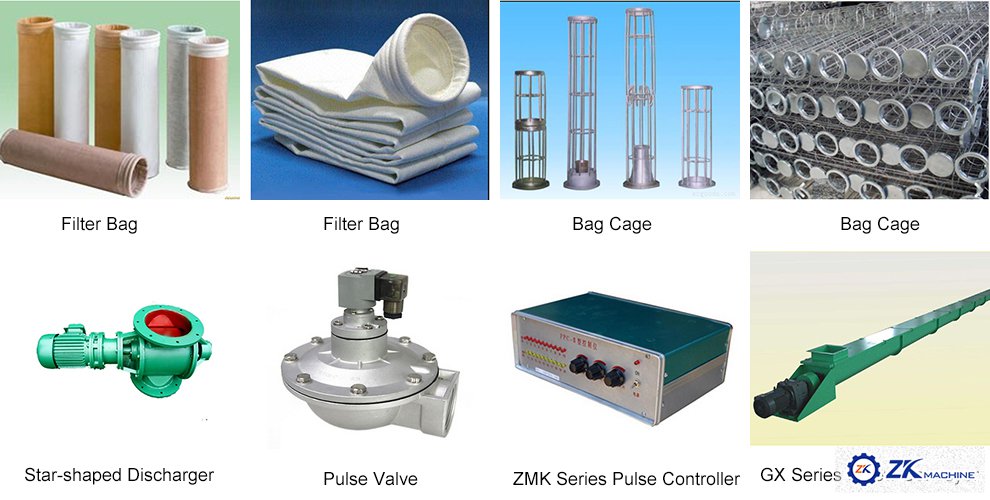

| Rotary discharger YJD-26 | Outlet:400×400,Rev.speed:45r/min,Power of reducer:2.2kW,Capacity:72.2m³/h 1 set for single row,2 sets for double row. | ||||||||||||

| Screw conveyor | Specification | Dia.:Φ400,Capacity:38m³/h,1 set for single row,2 sets for double row. | |||||||||||

| Reducer | Model:XWD5.5-7-1/59,power:5.5kW | ||||||||||||

| Air slide | If the inlet dust concentration is more than 700g/m³,the bag fiterwith air slide or big size screw conveyor should be selected. | ||||||||||||

| Size and material of bags | Dia.×L:Φ130×2450mm,Gross weight of polyester needle-felt:450g/m²,working temp.:120℃ | ||||||||||||

| Area of insulating layer(m²) | 110 | 120 | 130 | 140 | 150 | 160 | 175 | 210 | 245 | 280 | 315 | 350 | |

| Total weight (approx.)(kg) | 11290 | 13100 | 16070 | 18270 | 20350 | 22940 | 27220 | 32660 | 38100 | 43540 | 48990 | 54430 | |