- +86 15738871677

- +86 15738871677

- ec22@zkcorp.com

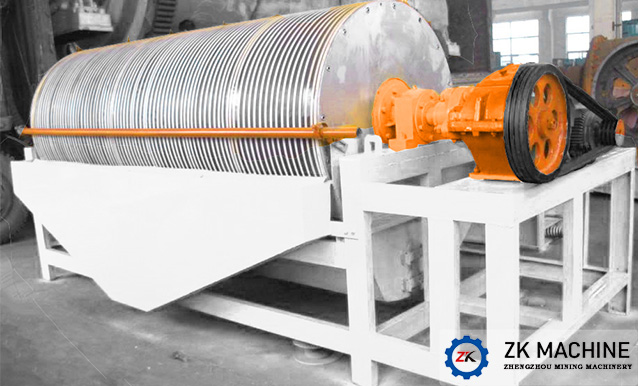

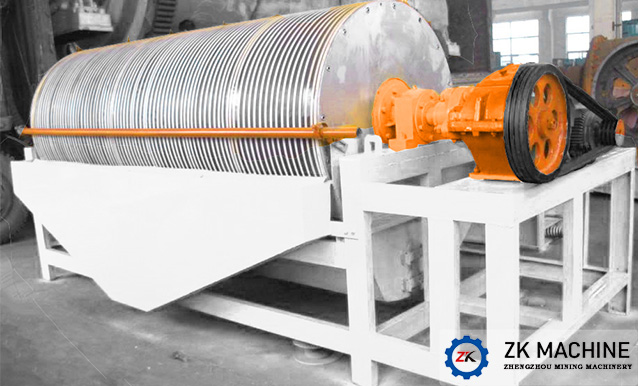

Model: CTB6012 -- CTB1230

Shell Dia: 600 - 1500 (mm)

Shell Length: 1200 - 3000 (mm)

Capacity: 10 - 280 (t/h)

|

Model |

Shell Diameter (mm) |

Shell Length |

Magnetic Strength |

Revolving Speed (r/min) |

Feeding Size |

Capacity |

Power |

|

CTB6012 |

600 |

1200 |

MT>100 |

<35 |

2-0 |

10-20 |

1.5 |

|

CTB6018 |

600 |

1800 |

MT>100 |

<35 |

2-0 |

15-30 |

2.2 |

|

CTB7518 |

750 |

1800 |

MT>120 |

<35 |

2-0 |

20-45 |

2.2 |

|

CTB9018 |

900 |

1800 |

MT>130 |

<35 |

3-0 |

40-60 |

3 |

|

CTB9021 |

900 |

2100 |

MT>130 |

<35 |

3-0 |

45-60 |

3 |

|

CTB9024 |

900 |

2400 |

MT>130 |

<28 |

3-0 |

45-70 |

4 |

|

CTB1018 |

1050 |

1800 |

MT>135 |

<20 |

3-0 |

50-75 |

5.5 |

|

CTB1021 |

1050 |

2100 |

MT>135 |

<20 |

3-0 |

50-100 |

5.5 |

|

CTB1024 |

1050 |

2400 |

MT>135 |

<20 |

3-0 |

60-120 |

5.5 |

|

CTB1218 |

1200 |

1800 |

MT>135 |

<18 |

3-0 |

80-140 |

5.5 |

|

CTB1224 |

1200 |

2400 |

MT>135 |

<18 |

3-0 |

85-180 |

7.5 |

|

CTB1230 |

1200 |

3000 |

MT>135 |

<18 |

3-0 |

100-180 |

7.5 |

|

CTB1530 |

1500 |

3000 |

MT>135 |

<14 |

3-0 |

170-280 |

11 |