- +86 18037866379

- +86 18037866379

- mic@zkcorp.com

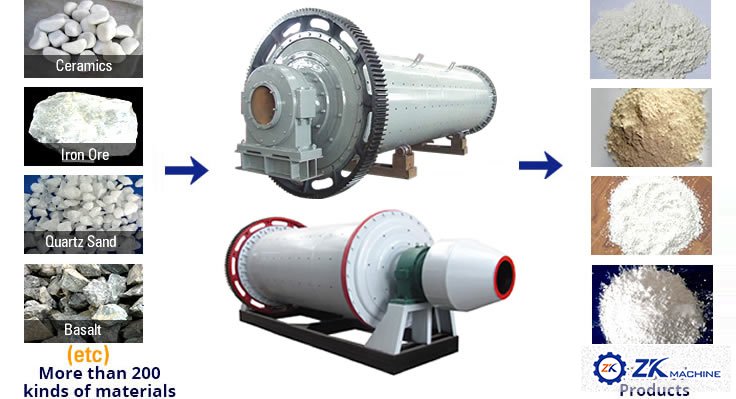

Model : Φ750x750 - Φ1830×6400 (mm)

Outlet size: 0.074 - 0.4 (mm)

Capacity: 0.18 - 15 (t/h)

Application: Gold Ore, Iron Ore, Manganese Ore, Slag, Feldspar, Limestone, etc.

|

Model (mm) |

Rotating Speed (r/min) |

Weight of ball (t) |

Inlet Size (mm) |

Outlet Size (mm) |

Capacity (t/h) |

Motor Power (kW) |

Weight (t) |

Remarks |

|---|---|---|---|---|---|---|---|---|

| Φ750×750 | 40.56 | 0.5 | ≦20 | 0.074-0.3 | 0.18-0.5 | 15 | 2.774 | Energy saving mill |

| Φ900×3000 | 36 | 2.7 | ≦20 | 0.074-0.89 | 1.1-3.5 | 22 | 6.8 | Dry type |

| Φ900×3000 | 39 | 5.8 | ≦25 | 0.075-0.89 | 0.8-3.1 | 22 | 7.1 | Wet lattice |

| Φ1200×4500 | 33 | 13 | ≦25 | 0.074-0.4 | 0.7-8 | 45 | 14.2 | Wet lattice |

| Φ1500×5700 | 30 | 25 | ≦25 | 0.074-0.6 | 4-14 | 130 | 25 | Wet lattice |

| Φ1830×6400 | 24.1 | 21 | ≦25 | 0.074-0.4 | 6.5-15 | 210 | 34 | Wet overflow |

| No. | Name | Material | Qty. | Part | Remarks |

|---|---|---|---|---|---|

| 1 | Spherical tile (main bearing) | HT200/ZPbSb15Sn10 | 2 | Main bearing | Different specifications, different materials |

| 2 | Cylinder liner | ZGMn13 (General) | As required | Cylinder | Different specifications, different quantities |

| 3 | Mill door liner | ZGMn13 (General) | As required | Cylinder | Different specifications, different quantities |

| 4 | Mill door (manhole cover) | ZGMn13 (General) | As required | Cylinder | Different specifications, different quantities |

| 5 | Mill door liner | ZGMn13 (General) | As required | Cylinder | Different specifications, different quantities |

| 6 | Gear | 45#Forge | 1 | Transmission device | Different requirements, different materials |