- +86 15738871677

- +86 15738871677

- ec22@zkcorp.com

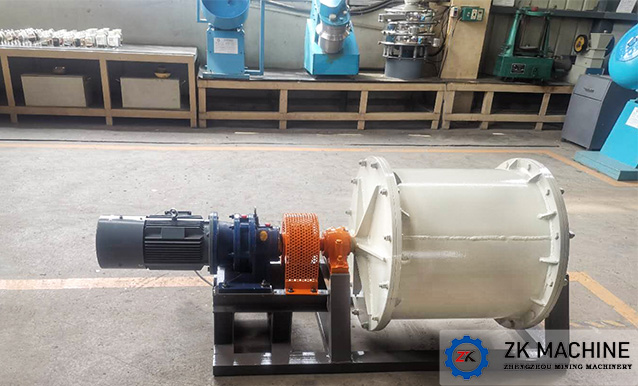

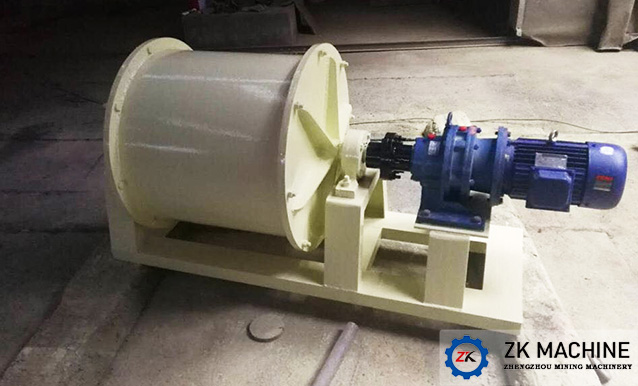

Model: Φ305x350 mm -- Φ1800x2100 mm

Type: Batch Ball Mill, Lab Ball Mill, Small Ceramic Ball Mill, etc.

Loading Weight: 0.2 tons -- 1.5 tons

Application: Ore, coal, cement, feldspar, limestone, etc.

|

Cylinder size (mm) |

Loading weight (t) |

Rotating speed of cylinder (r/min) |

Motor Power (kW) |

Weight (t) |

|---|---|---|---|---|

| Φ910×1120 | 0.2 | 35 | 2.2 | 1.91 |

| Φ1200×1420 | 0.5 | 31.45 | 4 | 2.5 |

| Φ1400×1800 | 1 | 27 | 7.5 | 3 |

| Φ1800×2100 | 1.5 | 23 | 11 | 4.5 |