Introduction

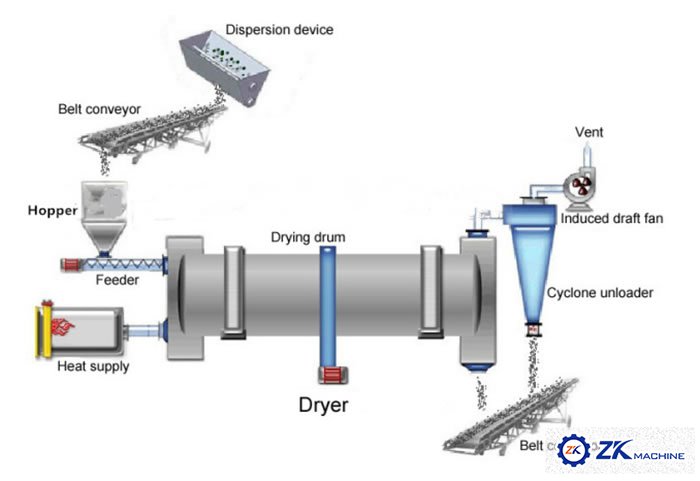

Fertilizer rotary dryer is an important component in fertilizer making line. It can dry not only organic fertilizer but also inorganic fertilizer and other kinds of fertilizers.

Generally speaking it can dry the material from 30-40% humidity to 1-5% humidity.

Fertilizer rotary dryer machine is a set of equipment to process mass materials. Due to reliable performance, high capacity, wide adaptability range, small flow resistance, convenient operation, low consumption, high handling capacity, organic fertilizer rotary dryer machine is widely used in construction, metallurgy, chemical, coal, pharmaceutical and mining industry. Fertilizer rotary dryer machine is generally applicable for granular materials, materials of high moisture, viscous and pasty materials by mixed with other materials.

Service of ZK Corp:

1.Our factory is professional produce dryer and briquette machine and rotary kiln. we will offer the best price for customer .hope you can visit our factory and test machine.

2.this dryer can use coal, charcoal, wood, gas and others use fuel .

3.when you order the machine, we will send our engineer install the machine and train the worker how to run the machine until the full line run well.

Parameter

|

Spec./m

(Dia.×Length)

|

Shell Cubage

(m³)

|

Capacity

(t/h)

|

Installation

Obliquity

(%)

|

Highest Inlet

Air Temperature

(℃)

|

Main Motor

(kw)

|

Weight

(t)

|

|

Φ1.2×8.0

|

9.0

|

1.9~2.4

|

3~5

|

700~800

|

7.5

|

9

|

|

Φ1.2×10

|

11.3

|

2.4~3.0

|

3~5

|

700~800

|

7.5

|

11

|

|

Φ1.5×12

|

21.2

|

4.5~5.7

|

3~5

|

700~800

|

15

|

18.5

|

|

Φ1.5×14

|

24.7

|

5.3~6.6

|

3~5

|

700~800

|

15

|

19.7

|

|

Φ1.5×15

|

26.5

|

5.7~7.1

|

3~5

|

700~800

|

15

|

20.5

|

|

Φ1.8×12

|

30.5

|

6.5~8.1

|

3~5

|

700~800

|

18.5

|

21.5

|

|

Φ1.8×14

|

35.6

|

7.6~9.5

|

3~5

|

700~800

|

18.5

|

23

|

|

Φ2.2×12

|

45.6

|

9.7~12.2

|

3~5

|

700~800

|

22

|

33.5

|

|

Φ2.2×14

|

53.2

|

11.4~14.2

|

3~5

|

700~800

|

22

|

36

|

|

Φ2.2×16

|

60.8

|

13.0~16.2

|

3~5

|

700~800

|

22

|

38

|

|

Φ2.4×14

|

63.3

|

13.5~16.9

|

3~5

|

700~800

|

37

|

45

|

|

Φ2.4×18

|

81.4

|

17.4~21.7

|

3~5

|

700~800

|

37

|

49

|

|

Φ2.4×20

|

90.4

|

19.3~24.1

|

3~5

|

700~800

|

45

|

54

|

|

Φ2.4×22

|

99.5

|

21.2~26.5

|

3~5

|

700~800

|

45

|

58

|

|

Φ2.6×24

|

127.4

|

27.2~34.0

|

3~5

|

700~800

|

55

|

73

|

|

Φ3.0×20

|

141.3

|

30.1~37.7

|

3~5

|

700~800

|

75

|

85

|

|

Φ3.0×25

|

176.6

|

37.7~47.1

|

3~5

|

700~800

|

75

|

95

|

|

Φ3.2×25

|

201

|

42.9~53.6

|

3~5

|

700~800

|

90

|

110

|

|

Φ3.6×28

|

285

|

60.8~76.0

|

3~5

|

700~800

|

160

|

135

|

Technical parameters of indirect heat dryer:

Shell

diameter

×shell

Length

Items |

Inside

diameter

of outer

shell

(mm) |

Inside

diameter

of inner

shell

(mm) |

Shell

Length

(m) |

Shell

cubage

(m³) |

Shell

obliquity |

Lifting

blade

form |

Highest

inlet air

temperature

(℃) |

Dimensions

(m) |

|

Φ1.5×15m |

1500 |

500 |

15 |

20.27 |

3-5% |

Lifting form |

850 |

16.2×2.7×2.7 |

|

Φ1.5×17m |

17 |

22.97 |

18.2×2.7×2.7 |

|

Φ1.5×19m |

19 |

25.68 |

20.0×2.9×2.9 |

|

Φ1.8×21m |

1800 |

650 |

21 |

35.91 |

3-5% |

Lifting form |

850 |

22.5×2.7×2.7 |

|

Φ1.8×23m |

23 |

39.33 |

24.5×2.9×2.9 |

|

Φ1.8×25m |

25 |

42.75 |

26.5×2.9×2.9 |

|

Φ2.2×21m |

2200 |

800 |

21 |

58.10 |

3-5% |

Lifting form |

850 |

---- |