Working principle and characteristics of FU scraper conveyor

Date:2022-08-19 09:58:26

Author:admin

Views:

117

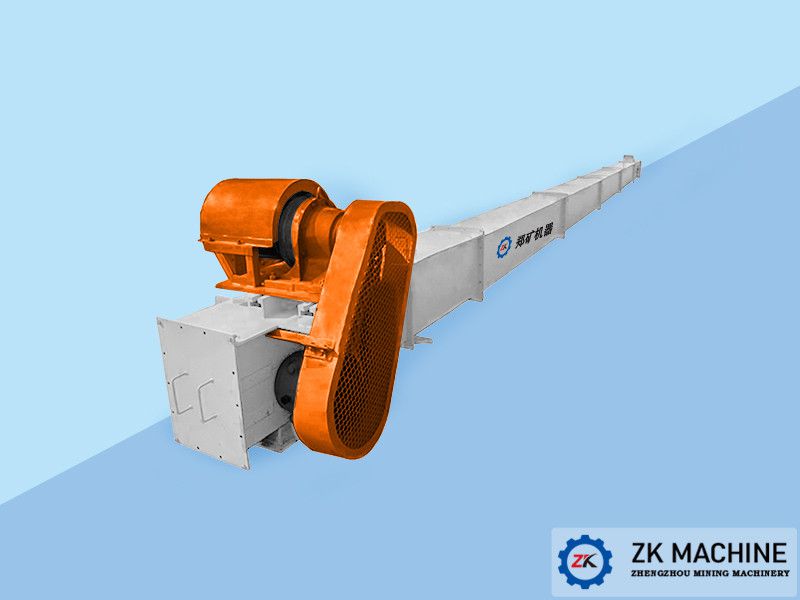

The FU type buried scraper conveyor produced by Henan Zhengzhou Mining Machinery is a product designed by our factory to absorb the experience at home and abroad for conveying powder and granular materials horizontally or inclined (≤15℃). The product has the advantages of novel structure, reasonable design, reliable operation, energy saving and high efficiency, and long service life. Since its development, it has been widely used in building materials, construction, chemical industry, thermal power, grain processing, mining, machinery, smelting, transportation, ports and transportation industries.

Working principle:

There is mutual internal friction and internal pressure between the particles of the bulk material, and they are driven by the movement of the conveyor chain in the trough of the chain conveyor and are driven by the same direction of movement, which increases the internal friction and pressure between the bulk materials. When the internal friction force is greater than the friction force between the material and the wall of the machine groove, the material moves forward under the drive of the conveyor chain, and the increased internal force ensures the stable state between the material layers. to form a continuous flow as a whole. When the ratio of the height of the material layer to the width of the machine groove meets certain conditions, the logistics is stable, and the material speed is approximately equal to the chain speed.

Main features:

1. Large conveying capacity, high-efficiency conveyor allows conveying a large amount of materials in a small space, and the conveying capacity can reach 600m³/h.

2. The conveying energy consumption is low. With the help of the internal friction between the materials, it becomes the pulling force that pushes the materials, which saves 50% of electricity compared with the screw conveyor. It is energy-saving and durable, with low use cost and less maintenance. In order to ensure the normal operation of the main engine to increase output, reduce consumption and improve economic benefits.

3. Excellent sealing and safety, the fully sealed casing makes the dust seamless and drillable, and the operation is safe, environmentally friendly and reliable.

4. Long service life. The conveyor chain made of alloy steel after advanced heat treatment has a normal service life of more than 5 years, and the life of the rollers on the chain (according to different materials) ≥ 2-3 years.

5. The process layout is flexible. It can be arranged on an elevated, bottom surface or pit, or can be installed horizontally or on a slope (≤15°C), or can be installed horizontally and on a slope with the same machine, with multi-point feeding and discharging layout.

6. Our company's product series is complete, and the FU series has various models such as FU150, FU200, FU270, FU350, FU410, FU500, FU600, and FU700 to choose from.