Model: GX150 -- GX600

Max Capacity: 255.9 (m³/h)

Rov. Speed: 20 - 90 (r/min)

Conveying Material: Coal, slag, cement, clay powder, sand, gravel, etc.

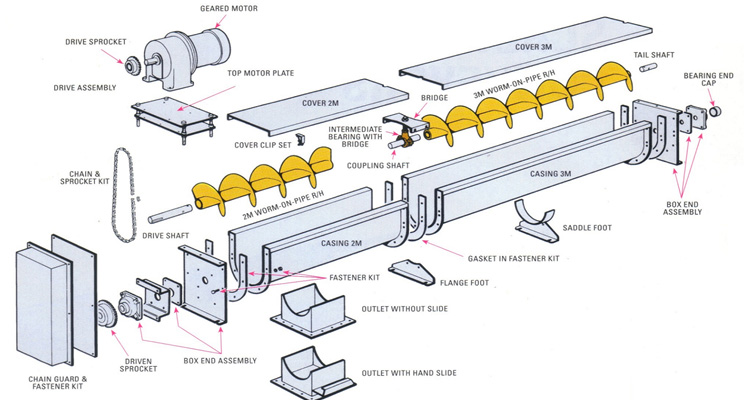

GX Type Screw conveyor is a kind of continuous conveying equipment without flexible traction mechanism. It mainly used to convey all kinds of powdery, granular bulk materials, such as clay powder, coal, cement, sand, grains, and small lump coal, gravel, scrap iron etc. But not suitable for sticky agglomerate, perishable materials.

Screw conveyor has horizontal and inclined arragement. It can work with other conveying device to complete the concentrated transportation, distribution, agitation, mixing, dehydration, dosing, unload, stacking operation etc.

|

Model |

Screw dia. (mm) |

Pitch (mm) |

Rev. Speed (r/min) |

Capacity (m³/h) |

Conveying Distance |

|

GX200 |

200 |

200 |

50~90 |

7~12 |

2~15 |

|

GX250 |

250 |

200 |

45~90 |

10~20 |

2~20 |

|

GX300 |

300 |

300 |

40~80 |

15~30 |

2~20 |

|

GX400 |

400 |

300 |

35~70 |

25~55 |

2~25 |

|

GX500 |

500 |

400 |

35~65 |

45~90 |

2~25 |

|

Wearing Parts List: |

|||||

|

No. |

Name |

Quantity |

No. |

Name |

Quantity |

|

1 |

Screw Blade |

1 |

4 |

Shaft |

4 |

|

2 |

Bearing |

2 |

5 |

Transmission Shaft Coupling |

1 |

|

3 |

Nylon Pin |

8 |

6 |

Reducer Coupling |

1 |

1. It achieved clean and environmentally friendly production, especially suitable for conveying dusty, hot (under 200 ℃) and sharp odour material.

2. The wear treated screw is more wearable and stronger than traditional common screw. It can significantly increase the service life of the screw

3. It can achieve multi-point feeding and multi-point discharging according to user's process layout.

4. The redesigned discharging structure makes the discharging smoother.

5. Compact structure, less wearing parts, convenient to install, operate and maintain.