Volume: 67300 - 314000 (m³/h)

Filtration area: 935 - 4361 (㎡)

Net filtration area: 4205 (㎡)

Dust content at inlet: < 1300 (g/m³)

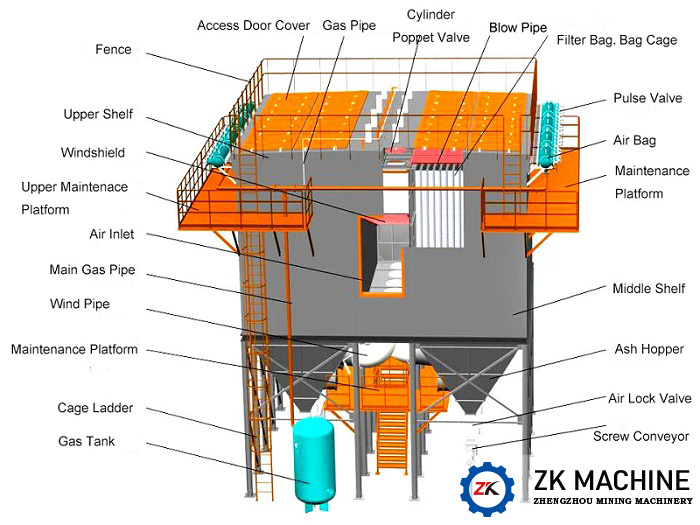

Pulse Jet Bag Filter incorporates the advantages of the several kinds of bag filters and is equipped with high performance pulse valve. This kind of bag filter can be used in building material, metallurgy, chemical and refractory industries, especially the crushing, packing, clinker cooling and grinding workshops in cement production. It is also suitable for dust collection of coal grinding after some modification.

Suitable for application in: cement, metallurgy, electric power, chemical and other industries of dust gas purification and fine powder material recycling collection.

According to different Bag Quantity, Pulse Dust collector could be classified as 32 bags/room, 64 bags/room, 96 bags/room, 128 bags/room. Each kind will be divided into many different type-33 kinds in total.

| Model | PPC96-4 | PPC96-5 | PPC96-6 | PPC96-7 | PPC96-8 | PPC96-9 |

PPC96- 2×5 |

PPC96- 2×6 |

PPC96- 2×7 |

PPC96- 2×8 |

PPC96- 2×9 |

PPC96- 2×10 |

|

| Air volume (m³/h) | 26800 | 33400 | 40100 | 46800 | 53510 | 60100 | 66900 | 80700 | 94100 | 107600 | 121000 | 134500 | |

| Air speed (m/min) | 1.2~2.0(Filtering speed should be determined by different dust collecting location) | ||||||||||||

| Total filtering area (m²) | 372 | 465 | 557 | 650 | 744 | 836 | 929 | 1121 | 1308 | 1494 | 1681 | 1868 | |

| Net filtering area (m²) | 279 | 372 | 465 | 557 | 657 | 744 | 836 | 1028 | 1215 | 1401 | 1588 | 1775 | |

| Qty of bag(pc) | 384 | 480 | 576 | 672 | 768 | 864 | 960 | 1152 | 1344 | 1536 | 1728 | 1920 | |

| Pressure drop (Pa) | 1470~1770 | ||||||||||||

| Negative pressure (Pa) | 5000 | ||||||||||||

| Inlet dust concentration (g/m³) | < 1300 | ||||||||||||

| Outlet dust concentration (mg/m³) | ≤30 | ||||||||||||

| Air cleaning compressed ain | Pressure (MPa) | 0.5~07 | |||||||||||

| Consumption (m³/min) | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3 | 3.4 | 4.2 | 4.8 | 5.4 | 6 | |

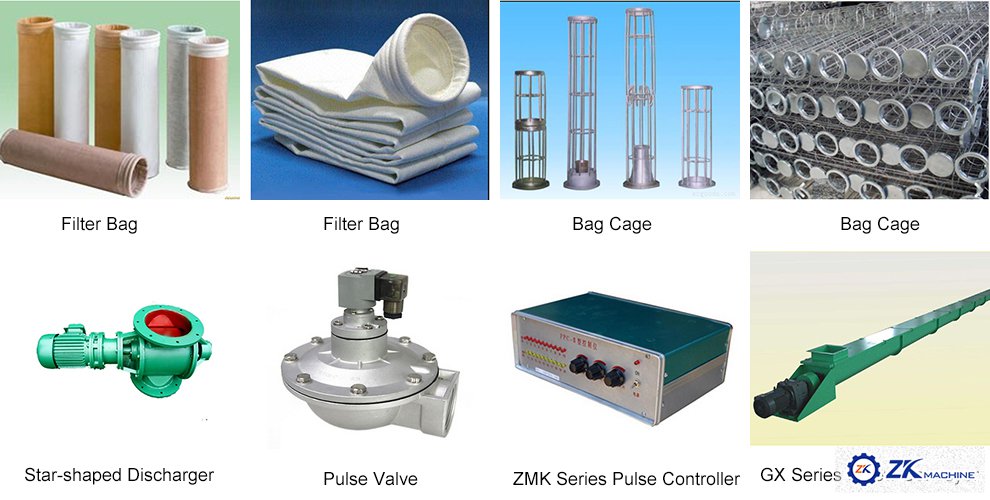

| Pulse valve | Qty(pc) | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 14 | 16 | 18 | 20 |

| Size(inch) | 2~1/2” | ||||||||||||

| Lift valve (with cylinder) | Qty(pc) | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 14 | 16 | 18 | 20 |

| Size (mm) | Dia.Of lift valve:Φ725,Dia.Of cylinder:φ100 | ||||||||||||

| Rotary discharger YJD-26 | Outlet:400×400,Rev.speed:45r/min,Power of reducer:2.2kW,Capacity:72.2m³/h 1 set for single row,2 sets for double row. | ||||||||||||

| Screw conveyor | Specification | Dia.:Φ400,Capacity:38m³/h,1 set for single row,2 sets for double row. | |||||||||||

| Reducer | Model:XWD5.5-7-1/59,power:5.5kW | ||||||||||||

| Air slide | If the inlet dust concentration is more than 700g/m³,the bag fiterwith air slide or big size screw conveyor should be selected. | ||||||||||||

| Size and material of bags | Dia.×L:Φ130×2450mm,Gross weight of polyester needle-felt:450g/m²,working temp.:120℃ | ||||||||||||

| Area of insulating layer(m²) | 110 | 120 | 130 | 140 | 150 | 160 | 175 | 210 | 245 | 280 | 315 | 350 | |

| Total weight (approx.)(kg) | 11290 | 13100 | 16070 | 18270 | 20350 | 22940 | 27220 | 32660 | 38100 | 43540 | 48990 | 54430 | |

1. New and advanced dust removing concept. No air pipe. Pulse valve is assembled at the side the chamber shell or top. No need to disassemble and assemble the air pipe when replacing the bags.

2. High performance pulse is applied to replace many smaller pulse to reduce the maintenance as much as possible.

3. Multi-chamber and off-line dust removing. Long life of filter bag.

4. Available for high density dust containing air collection, for example, O-Sepa separator, the dust content of which will reach 1000g/Nm3.

5. Air tank will reduce the pressure decrease caused by equipment.