- Home > Products > Drying Equipment >

Model: Φ1.0×10 - Φ5.0×50 (m)

Capacity: 1 - 60 (t/h)

Power: 11 - 400 (kW)

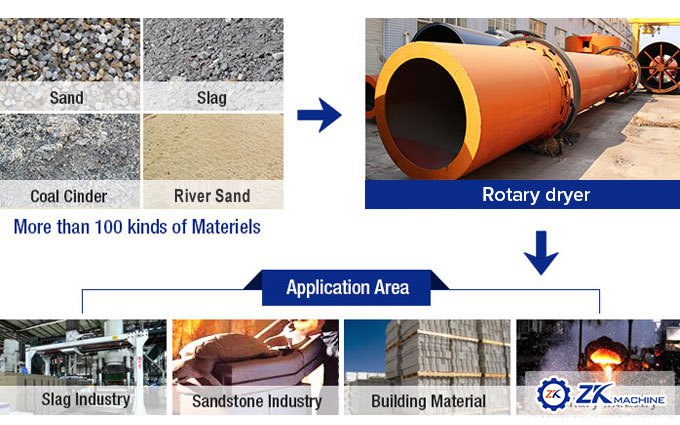

Application: cement, fly ash, slag, coal, gypsum, gangue, limestone, ores etc.

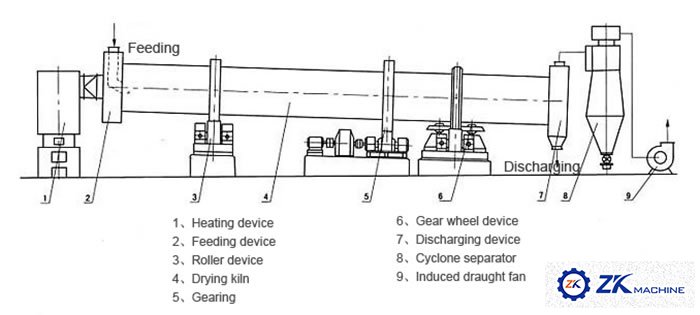

Rotary dryer is mainly used for the drying various materials.The material inside the rotary dryer has heat exchange with the high temperature flue gas through shell rotating and material lifting by lifter. The rotary dryer has many good characters like: high efficiency, big capacity, high running rate, saving energy, easy for maintenance, long working life. Variety angle of the lifter will increase the heating exchange rate and short drying time. Feeding and discharging unit is installed with thermocouple to control drier temperature. The temperature change of drier's feeding end can be indicated by the thermometer to control the inner drier temperature (generally 250-350°C)

| Model (m) | Shell | Capacity (t/h) | Motor | Power (kW) | Reducer | |||

| Inner Diameter (mm) | Length (mm) | Slope (°) | Rev.Speed (rpm) | Motor Model | ||||

| Ø1.2X12 | 1200 | 12000 | 1.8 | 5 | 2-5 | YI60LM-6 | 11 | ZQ500 |

| Ø1.5X15 | 1500 | 15000 | 1.8 | 4.28 | 4-5 | YI60L-6 | 18.5 | ZQ650 |

| Ø1.8X18 | 1800 | 18000 | 1.8 | 5 | 6-8 | Y200LI-6 | 22 | ZQ650 |

| Ø2.0X20 | 2000 | 20000 | 2 | 3.38 | 7-10 | Y200L2-6 | 30 | ZQ650 |

| Ø2.2X22 | 2200 | 22000 | 1.8 | 2.8 | 9-14 | Y250M-6 | 45 | ZQ650 |

| Ø2.4X24 | 2400 | 24000 | 2.5 | 2.82 | 14-16 | Y280S-6 | 55 | ZQ750 |

| Ø2.8X28 | 2800 | 28000 | 2.5 | 2.55 | 20-22 | Y315S-6 | 90 | ZL115 |

| Ø3.0X30 | 3000 | 30000 | 2.5 | 2.69 | 22-24 | Y315LI-6 | 132 | ZL130 |

| Ø3.2X32 | 3200 | 32000 | 2.5 | 2.6 | 24-26 | Y315M-4 | 200 | ZSY450 |

| Ø3.6X36 | 3600 | 36000 | 2.5 | 2.51 | 30-40 | Y315L2-4 | 315 | ZL130 |

| Ø4.0X40 | 4000 | 40000 | 2.5 | 2.09 | 40-45 | YKK4003-4 | 400 | ZSY630 |

| Ø4.2X42 | 4200 | 42000 | 2.5 | 2.09 | 45-46 | YKK4005-4 | 400 | ZSY630 |

| Ø4.5X45 | 4500 | 45000 | 2.5 | 1.92 | 46-50 | YKK4502-4 | 500 | MH3S230 |

| Ø4.8X48 | 4800 | 48000 | 2.5 | 1.92 | 50-55 | YKK4504-4 | 630 | MH3S250 |

| Ø5.0X 50 | 5000 | 50000 | 2.5 | 1.92 | 55-60 | YKK4505-4 | 710 | MH3S260 |

1. Shell adopts assembled structure, and its precision has been improved a lot, which will be convenient for transport.

2. According to different fuel properties, suuitable raising plate will be used. This can make material receive more heat exchange.

3. Sealing is simple but efficient, which can improve capacity and improve whole machine performance.

4. Its matching combustion furnance is energy-saving type, which takes small area and is easy to adjuest.