- Home > Products > Drying Equipment >

Capacity: 1 - 40 (t/h)

Powder: 7.5 - 132 (kW)

Slope: 3.5% - 5%

Applied material: slag, mineral powder, fly ash, coal powder, etc.

Blast furnace slag dryer is defined as a device in which solids are dried while being transported along the interior of a rotating cylinder equipped with lifting flights to shower the solids through the hot gas. Through heat exchange, it is to r educe or minimize moisture content of the material it is drying. By bagasse drying machine, people could get the finished product which is suitable for packing, transportation, subsequent process, etc.

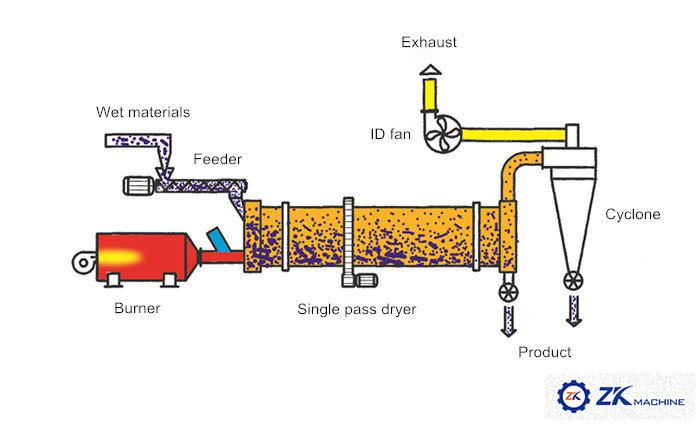

Flowchart Of Slag Dryers:

| MODEL | CAPACITY (t/h) | SLOPE (%) | GEARBOX | MOTOR | POWER (kW) |

| Ø1.0×10m | 1-2 | 5 | ZQ400 | YCT200-4B | 7.5 |

| Ø1.2×12m | 2-3 | 5 | ZQ500 | YCT225-4A | 11 |

| Ø1.5×15m | 3-5 | 5 | ZQ500 | YCT225-4B | 15 |

| Ø1.8×18m | 4-6 | 4 | ZQ750 | YCT250-4B | 22 |

| Ø2.0×20m | 7-9 | 3.5 | ZQ750 | YCT280-4A | 30 |

| Ø2.2×22m | 8-10 | 3.5 | ZQ850 | YCT315-4A | 37 |

| Ø2.4×24m | 12-15 | 3.5 | ZQ850 | YCT315-4B | 45 |

| Ø2.8×28m | 16-22 | 3.5 | ZS145 | YCT355-4A | 55 |

| Ø3.0×30m | 20-25 | 3.5 | ZS165 | YCT355-4B | 75 |

| Ø3.2×32m | 28-32 | 3.5 | ZL130 | YCT355-4C | 90 |

| Ø3.6×36m | 38-40 | 3.5 | ZL130 | YVF2-315L2-6 | 132 |

1. Largely increase heat transfer rate and vaporization rate;

2. Vaporization capacity per hour is as much as 25-60 kg/m2, which is 1-2 times of traditional rotary dryer;

3. Output is raised by 50% and fuel consumption is reduced by 30%;

4. Drying efficiency is raised by 40%;

5. Save 40% space and civil investment and 20%equipment investment.