Capacity: 50 - 1500 (ton/day)

Raw Materials: Clinker, Gypsum, Slag, etc.

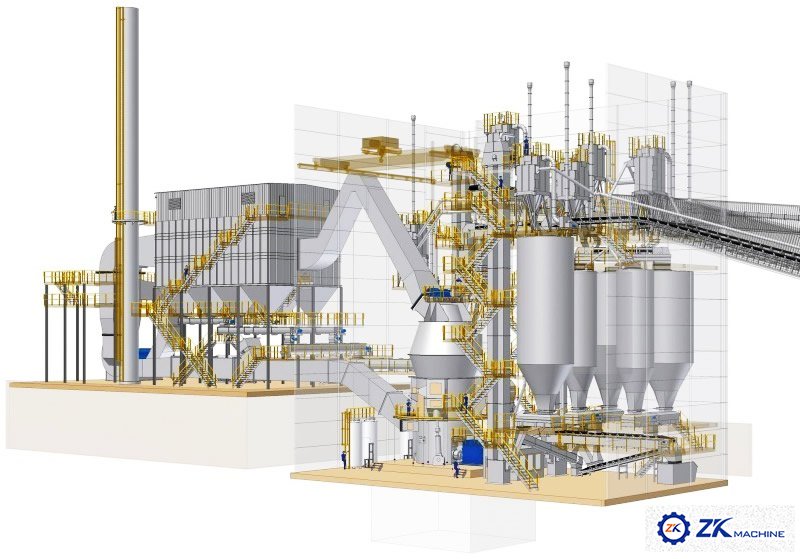

Main Equipment: Vertical Mill, Ball Mill, Bag Filter, Bucket Elevator, etc.

Application: Grinding System for Cement Production

We provide the full range service including design, manufacturing, installation and training for complete cement clinker grinding plant with capacity from 50t/d to 1500t/d.

The cement clinker grinding plant acts as an individual production line in the last period of the cement production process. In the finished product period, the cement clinker is ground by adding moderate mixing materials and then forms the finished cement. Main Equipments: Cement Ball Mill or Vertical Mill, Dust Collector, Powder Separator, Bucket Elevator, etc.

| No. | Item | Unit | Closed circuit production | ||||

| 1 | Factory capacity | ×10³ t/a | 100 | 160 | 250 | 350 | 500 |

| 2 | Main material usage | ||||||

| ① | Clinker | t/a | 80000 | 128000 | 200000 | 280000 | 400000 |

| ② | Gypsum | t/a | 5000 | 8000 | 12500 | 17500 | 25000 |

| ③ | Pozzolana | t/a | 15000 | 24000 | 37500 | 52500 | 75000 |

| 3 | Energy consumption | ||||||

| ① | Fresh water | t/a | 4000 | 7000 | 9000 | 12000 | 17000 |

| ② | Electrical | kWh/a | 3600000 | 5700000 | 8500000 | 1200000 | 17000000 |

| 4 | Layout transportation | ||||||

| ① | Land area | ㎡ | 15000 | 18000 | 20000 | 22000 | 24000 |

| 5 | Project invest | ||||||

| ① | Production line total invest | Ten | 600 | 1000 | 1500 | 2000 | 2850 |

| thousand | |||||||

| 6 | Workers | 30 | 35 | 35 | 35 | 35 | |

| 7 | Main equipment | ||||||

| ① | Ball mill | Φ2.2×6.5m | Φ2.4×11m | Φ3×11m | Φ3.2×13m | Φ3.5×13m | |

| 14t/h | 24t/h | 35t/h | 50t/h | 70t/h | |||

| 380kW | 630kW | 1250kW | 1600kW | 2000kW | |||

| ② | Belt conveyor | B500 | B650 | B650 | B800 | B1000 | |

| ③ | Mill outlet bucket elevator | TH315 | TH400 | NE100 | NE150 | NE200 | |

| ④ | Air classifier | NHX400 | NHX600 | NHX700 | NHX800 | NHX1000 | |

| (Osepa N250) | (Osepa N500) | (Osepa N750) | (Osepa N1000) | (Osepa N1500) | |||

| ⑤ | Bag filter | PPC32-4 | PPC32-6 | PPC64-5 | PPC64-6 | PPC64-7 | |

| (PPC64-6) | (PPC96-7) | (PPC96-2×5) | (PPC96-2×6) | (PPC96-2×10) | |||

| ⑥ | Finished production bucket elevator | TH250 | TH315 | NE50 | NE100 | NE100 | |

| ⑦ | Screw conveyor | LS400 | LS400 | LS500 | - | - | |

| ⑧ | Packer | 3 nozzle | 4 nozzle | 6 nozzle | 8 nozzle | 8 nozzle | |

| ⑨ | Belt weigher | B500×2000 | B650×2500 | B800×2500 | B800×2500 | B1000×3500 | |

1. The batching system have been adopt automatic quantitative feeding and measuring device, which have increase the material batching accuracy and also stablilizing the production’s quality.

2. Adopting tube mill or vertical roller mill to producing qualify cement according to the raw material’s condition of clients.

3. Producing system have adopt closed circuit to reduce the energy consumption of cement grinding. The single line scale can be from 15tpd to 1500tpd, which have been covered the cement factory’s different manufacture demand.

4. Adoption of High efficiency air classifier and pulse type bag filter have created the circumstance for energy saving and energy consumption reduction.

5. The mill and air classifier have adopt 3D computer design, which have reasonable structure and reliable operation.

6. The grinding system have adopt best ventilation air volume design, which will reduce the installed capacity.

7. Plant have high automation level, the operating process will adopt DCS central control system for adjustment, control and alarm in master control room, then the whole plant have less operator and also increase the working efficiency.