Capacity: 100 t/d - 2500 t/d

Type: Dry Process Cement Plant

Main Material: Limestone, Clay, Gypsum, Fly Ash, Slag

Main Equipment: Cement Mill, Cement Kiln, Dust Collector, Cement Mill, etc.

We provide the full range service including design, manufacturing, installation for new type dry method cement production line with capacity from 100t/d to 2500t/d.

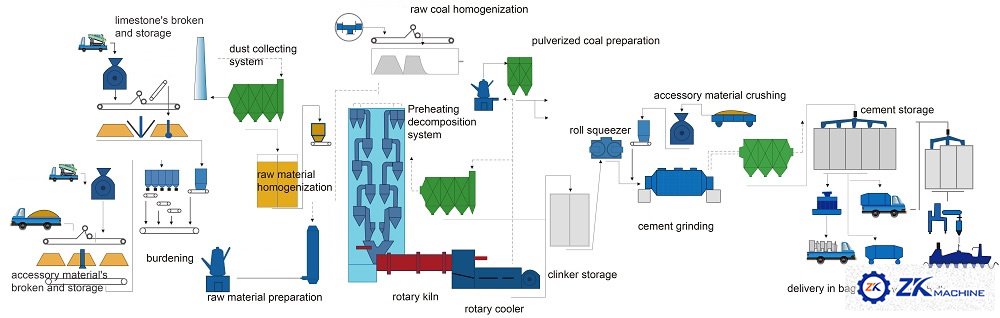

Process of Cement Production Plant:

1. Raw Materials

The main raw materials used in the cement manufacturing process are limestone, sand, shale, clay, and iron ore. The main material limestone is usually mined on site while the other minor materials may be mined either on site or in nearby quarries. Another source of raw materials is industrial by-products.

2. Raw Material Preparation

Mining of limestone requires the use of drilling and blasting techniques. Blasting produces materials in a wide range of sizes from approximately 1.5 meters in diameter to small particles less than a few millimeters in diameter.

Material is loaded at the blasting face into trucks for transportation to the crushing plant. Through a series of crushers and screening, the limestone is reduced to a size less than 100 mm.

Depending on size, the minor materials (sand, shale, clay, and iron ore) may or may not be crushed before being stored in separate areas.

Dry process cement production line (25-200t/d) Configuration

| Clinker Capacity | 25t/d | 50 t/d | 100 t/d | 150 t/d | 200 t/d | |

| Rotary kiln | Specification | Φ1.4×33m | Φ1.6/1.9×36m | Φ2.2×45m | Φ2.5×50m | Φ3×60m |

| Capacity | 1t/h | 2t/h | 4t/h | 6t/h | 8t/h | |

| Calcination | 1450 | 1450 | 1450 | 1450 | 1450 | |

| Temperature (℃) | ||||||

| Raw mill | Specification | Φ1.2×4.5m | Φ1.5×5.7m | Φ1.83×6.1m | Φ1.83×6.1m | Φ2.2×6.5m |

| Open circuit | Open circuit | Open circuit | Closed circuit | Closed circuit | ||

| Capacity | 1.7t/h | 4.5t/h | 9t/h | 12t/h | 16t/h | |

| Motor power | 55kW | 130kW | 210kW | 210kW | 310kW | |

| Cement mill | Specification | Φ1.2×4.5m | Φ1.5×5.7 | Φ1.83×6.1m | Φ1.83×6.1m | Φ2.2×6.5m |

| Open circuit | Open circuit | Open circuit | Closed circuit | Closed circuit | ||

| Capacity | 1.4t/h | 3.5t/h | 6.5t/h | 8t/h | 12t/h | |

| Motor power | 55kW | 130kW | 210kW | 210kW | 310kW | |

Dry process cement production line (300-1500t/d) configuration

| Clinker Capacity | 300t/d | 700 t/d | 1000 t/d | 1500 t/d | |

| Pre-heater | C1 | 2-Φ2500 | Φ3500 | Φ4800 | 2-Φ4000 |

| C2 | Φ3600 | Φ4800 | Φ4800 | Φ5800 | |

| C3 | Φ3600 | 2-Φ3700 | Φ5200 | Φ5800 | |

| C4 | Φ3600 | Φ4800 | Φ5200 | Φ6200 | |

| C5 | Φ3600 | Φ4800 | Φ5200 | Φ6200 | |

| Pre-calciner | Specification | Φ2200 | Φ2800 | Φ4800 | Φ5200 |

| Rotary kiln | Specification | Φ2.8×44m | Φ3×48m | Φ3.2×50m | Φ3.5×54m |

| Capacity | 12.5t/h | 30t/h | 42t/h | 63t/h | |

| Calcination temperature(℃) | 1450 | 1450 | 1450 | 1450 | |

| Raw mill | Specification | Vertical roller mill | Dry mill | Dry mill | HRM2800 |

| Φ1700 | Φ3.2×7+1.8m | Φ3.5×10m | Vertical roller mill | ||

| Capacity | 30t/h | 50t/h | 85t/h | 130~160t/h | |

| Motor power | 400kW | 1000kW | 1250kW | 1250kW | |

| Cement mill | Specification | Φ2.4×13m | Φ3×11m | Φ3.2×11m | Φ4.2×13.5m |

| Open circuit | Closed circuit | Closed circuit | Closed circuit | ||

| Capacity | 22t/h | 42t/h | 64t/h | 95t/h | |

| Motor power | 800kW | 1250kW | 1400kW | 3550kW | |

1.High Efficiency

Cement production line adopts advanced technology and equipment to raise technical level and to ensure design indexes. New five-stage cyclone pre-heater system, high efficiency air girder grate cooler, multi-passage pulverized coal burner, Davison heat temperature fan, jet pulse dust collector, as well as chain-board elevator, chain conveyor adopted in this production line can ensure that the technology is advanced compared to other production lines with the same scale.

2.Saving Energy

Measures have been taken to save energy and reduce consumption. using chain-board elevator and air slides, reliability of the system is enhanced and conveying energy consumption is decreased.

3.Environmental protection

Effective measures have been taken to guarantee strict environment protection standards. Different efficient dust collectors are set at all dust producing points according to different characteristics of waste gas.

4.High degree of automation

There is no manual operation in the process of mill running, which realizes the automatic control with long-term, stable, effective, makes milling process more stable, realizes fine work of production.